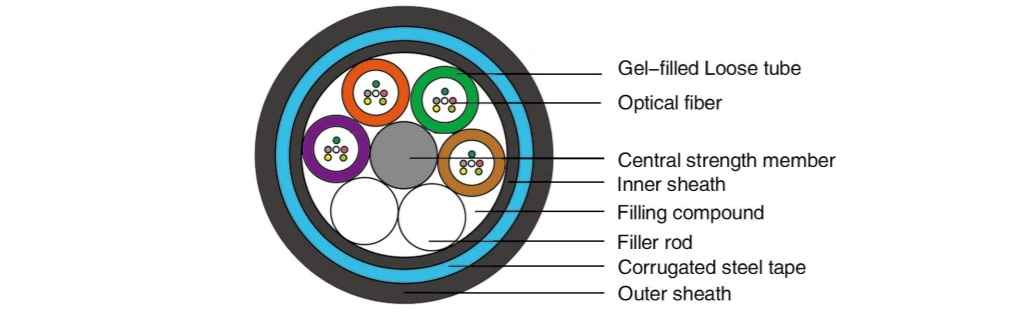

Fiber optic cable structure is a single mode or multi-mode fiber into the loose sleeve, and placed in the cable center.The steel wire reinforcement is twisted into a compact and round cable core around the central sleeve, the gap in the cable core is filled with water resistance, and the polyethylene sheath is formed into the cable.

Features:

·Good mechanical and temperature performance

·High strength loose tube that is hydrolysis resistant

·Special tube filling compound ensure a critical protection of fiber

·Specially designed compact structure is good at preventing loose tubes from shrinking ·PE sheath protects cable from ultraviolet radiation ·Good crush tolerance,applies for duct and directly buried distribution ·To assure the water-proof function by:

·Single steel wire as central strength member

·Special tube filling compound ensure a critical protection of fiber

·PSP enhances the ability to avoid moisture

·Fully filled in the cable

·Good water-blocking tape prevent the sinking vertically

Standars:

The products comply with relevant standards of YD/T,IEC and ITU.

Cable structure:

Colour Identification:

The color code of fibers and loose tube will be identification in accordance with the following color sequence,other sequence also is available.Can be customized according to customer needs.

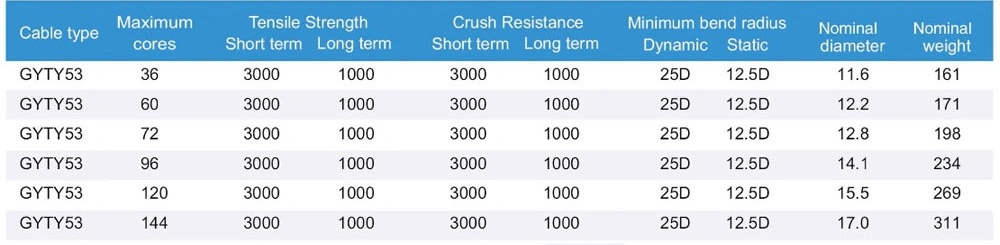

Technical Specification:

Remark:1.D is the diameter of the cable;

2.The above parameters are typical value;

3.The cable spec can be designed according to customer's requirement.

Packing:

Optical fiber

| G.652.D single mode fiber | |||

| characteristics | Conditions | Units | Specified values |

| Optical properties | |||

| Attenuation | 1310nm | dB/km | ≤0.34 |

| 1383nm | dB/km | ≤0.34 | |

| 1550nm | dB/km | ≤0.20 | |

| 1625nm | dB/km | ≤0.24 | |

| Attenuation vs. Wavelength Max. α difference @1310nm | 1285~1330nm | dB/km | ≤0.04 |

| @1550nm | 1525~1575nm | dB/km | ≤0.03 |

| Dispersion Coefficient | 1285nm~1340nm | ps/(nm.km) | -3.5~3.5 |

| 1550nm | ps/(nm.km) | ≤18 | |

| 1625nm | ps/(nm.km) | ≤22 | |

| Zero dispersion wavelength | nm | 1300nm~1324nm | |

| Zero dispersion slope | ps/(nm2.km) | ≤0.092 | |

| Typical Value | ps/(nm2.km) | 0.086 | |

| Polarization mode dispersion coefficient PMD | |||

| Single fiber maximum value | ps/ | ≤0.20 | |

| Fiber link value(M=20,Q=0.01%) | ps/ | ≤0.10 | |

| Typical value | ps/ | 0.04 | |

| Cable cut-off wavelength λcc | nm | ≤1260 | |

| Mode field diameter MFD | 1310nm | μm | 9.2±0.4 |

| 1550nm | μm | 10.4±0.5 | |

| Point Discontinuities | 1310nm | dB | ≤0.05 |

| 1550nm | dB | ≤0.05 | |

| Geometric characteristics | |||

| Cladding diameter | μm | 124.5±1.0 | |

| Cladding non-circularity | % | ≤1.0 | |

| Coating diameter | μm | 242±7 | |

| Coating-cladding concentricity error | μm | ≤12.0 | |

| Curl (radius) | M | ≥4 | |

| Delivery length | km/reel | 2.1~50.4 | |

| Environmental characteristics(1310nm,1550nm,1625nm) | |||

| Temperature Dependence Induced Attenuation | -60ºC ~+85ºC | dB/km | ≤0.05 |

| Temperature-Humidity Cycling Induced Attenuation | -10°C to +85°C, 98% RH | dB/km | ≤0.05 |

| Water Immersion Dependence Induced Attenuation | 23°C,for 30 days | dB/km | ≤0.05 |

| Damp Heat Dependence Induced Attenuation | 85°C and 85% RH,for 30 days | dB/km | ≤0.05 |

| Dry Heat Aging | 85ºC | dB/km | ≤0.05 |

| Mechanical properties | |||

| Proof test | GPa | ≥0.69(100kpsi) | |

| Macro-bend Induced Attenuation | |||

| 1 turnФ32mm | 1550nm | dB | ≤0.05 |

| 100 turns Ф60mm | 1625nm | dB | ≤0.05 |

| Coating Strip Force | Typical average force | N | 1.5 |

| Peak force | N | 1.0~8.9 | |

| Dynamic fatigue parameter | ≥20 | ||

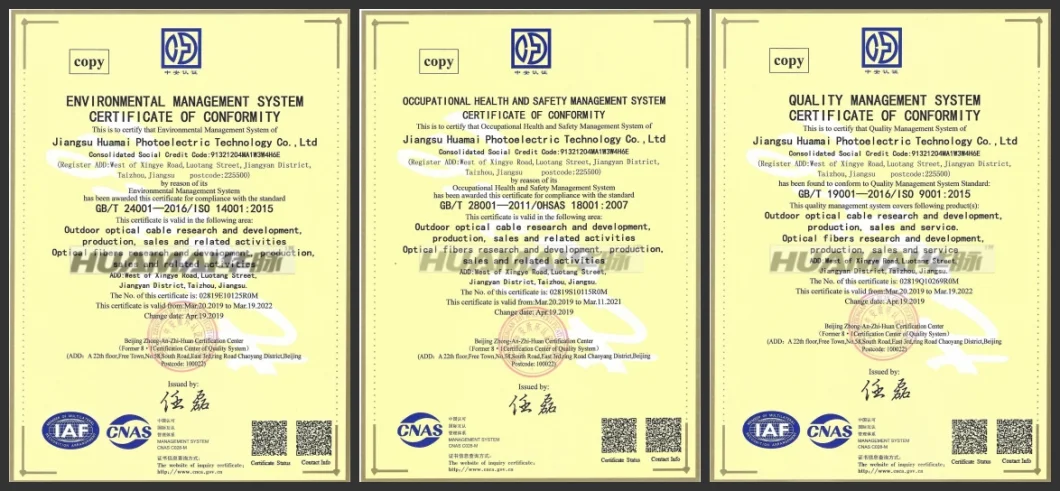

Certification

Our Company

Equipments:

Jiangsu Huamai Photoelectric Technology Co., Ltd. has complete production equipment for wiring, drawing, coloring, plastic coating, cable formation and sheathing, and complete hardware facilities.

At present, our annual production capacity is 10 million core km. Our fast delivery capability, perfect quality management system and perfect after-sales service system guarantee the confidence of our customers from domestic and abroad.

.

FAQ

Q1. Can I have a sample order for this product?

A: Yes, We are willing to provide samples to customers for testing. Mixed samples are acceptable.

Q2.How long is the delivery period?

A:Sample needs 3-5 days, mass production time needs 1-2 weeks for order quantity more than.

Q3.How to proceed an order for the sample/product?

A:Firstly, let us know your requirements or application.

Secondly, We quote according to your requirements or our suggestions.

Thirdly, customer confirms the samples and places deposit for formal order.

Fourthly , We arrange the production.

Q4: Do you offer guarantee for the products?

A: Yes, The warranty period is two years.

Click below and you can contact me >_<