Fiber to the home cabling system GJXFH/GJXH (4 core FTTH)

- Cable Description

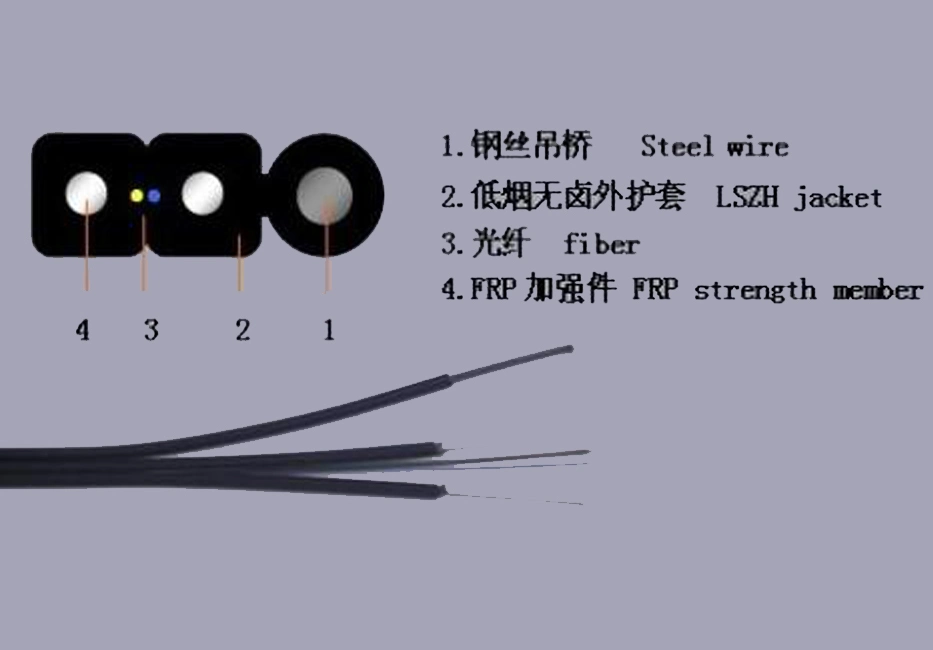

FTTH Cable directly connected to their homes, their bandwidth, wavelength and transmission technology type are not restricted. The optical fiber unit id positioned in the center. Two parallel strength member are placed at the two sides , then, the cable is completed with a black HDPE /LSZH sheath.

2. Cable Drawing

Note : Structure drawing just for reference, please check the following details.

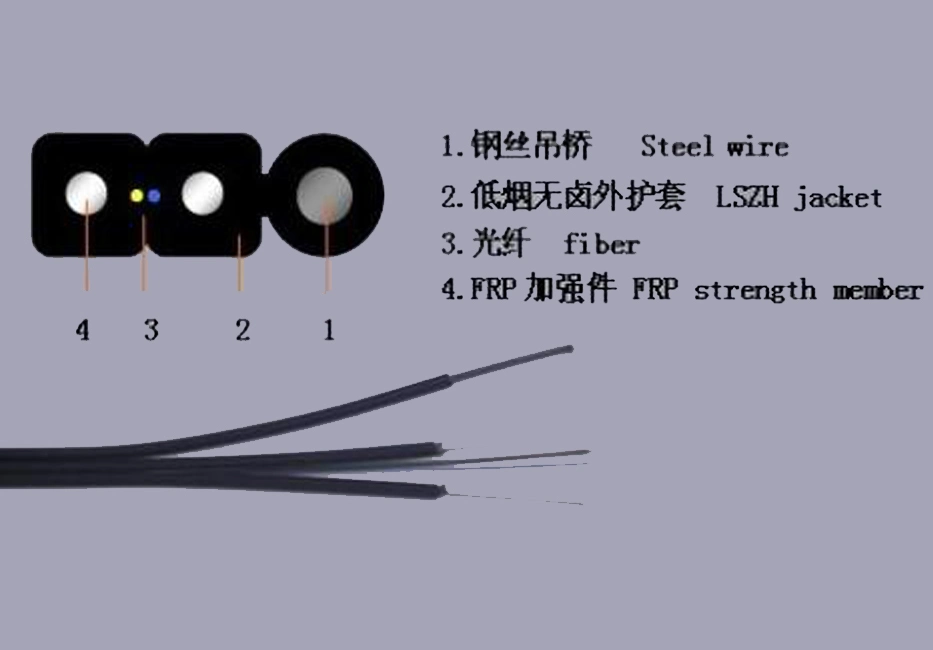

2. Cable Drawing

Note : Structure drawing just for reference, please check the following details.

- Application

- Adopted to indoor distribution;

- As pigtail of communication equipment;

- Suitable for communication equipment;

- Can be installed conveniently.

- Characteristics

- Weight, low cost, and practicability;

- Suitable for limited space field of the branch, indoor series;

- Laid to facilitate construction operations;part and the cable;

- Jacket use low smoke, halogen-free flame-retardant materials;

- Prevent lightning and strong electric environment;

- FRP or KFRP strengthen the component materials.

- Features:

Cable construction details

| Items | Description | |

| Number of fiber | 4 cores | |

| Fiber type | G657A | |

| Strength member | material | Galvanized steel wire/FRP/KFRP |

| diameter | 2*(0.5~0.8)mm | |

| Outer sheath | material | LSZH |

| diameter | 1.8±0.2mm | |

| Cable size (Height * width) | 4.0(±0.2) mm ×2.0 (±0.2)mm | |

| Cable sheath thickness | Max. 0.8mm/Min. 0.4mm | |

| Cable weight | 10KG±1KG | |

- Standard color of fiber and tube

The color of the individual fibers, shall be in accordance with the table as below:

| Standard Colour Identification | ||||

| No. | 1 | 2 | 3 | 4 |

| Color | Blue | Orange | Green | Brown |

Out sheath is black.

- Cable Mechanical characteristic

| Items | Description | |

| Installation Temperature range | -20--+60ºC | |

| Operation and transport temperature | -40-+70ºC | |

| Min Bending Radius(mm) | Long term | 10D |

| short term | 20D | |

| Allowable Tensile Strength(N) | Long term | 40 |

| short term | 80 | |

| Crush Load (N/100mm) | Long term | 500 |

| short term | 1000 | |

8. Requirement for Order:

- Fiber sort: Single mode G652,G655,G657, Multi mode 50/125,62.5/125,OM3,OM4.

- Fiber brand: YOFC, Corning, Fiberhome Fujikura, OFS etc.

3.Sheath material: PE,LSZH, PVC( can be required).

4.Sheath color: Black ,can be required.

5.The fiber and tube color: according to stranded color, can be required.

6.The cable Size: shall be in accordance with the table, can be required.

7.Length of cable: generally is 2KM, can be required.

8.Other requirement:can be negotiated.

9. Fiber characteristic

4.Sheath color: Black ,can be required.

5.The fiber and tube color: according to stranded color, can be required.

6.The cable Size: shall be in accordance with the table, can be required.

7.Length of cable: generally is 2KM, can be required.

8.Other requirement:can be negotiated.

9. Fiber characteristic

| Fiber style | Unit | SM G652D | SM G657A1 | SM G657A2 | ||

| condition | nm | 1310/1550 | 1310/1550 | 1310/1550 | ||

| attenuation | dB/km | ≤0.36/0.23 | ≤3.5/0.21 | ≤3.5/0.21 | ||

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ≤18 | ≤18 | |

| 1550nm | Ps/(nm*km) | ≤22 | ≤22 | ≤22 | ||

| Zero dispersion wavelength | nm | 1312±10 | 1312±10 | 1300-1324 | ||

| Zero dispersion slope | ps/(nm²×Km) | ≤0.091 | ≤0.090 | ≤0.092 | ||

| PMD Maximum Individual Fiber | [ps/√km] | ≤0.2 | ≤0.2 | ≤0.2 | ||

| PMD Design Link Value | ps/(nm²×Km) | ≤0.08 | ≤0.08 | ≤0.08 | ||

| Fiber cutoff wavelength λc | nm | >=1180,≤1330 | >=1180,≤1330 | >=1180,≤1330 | ||

| Cable cutoff wavelength λcc | nm | ≤1260 | ..... | ..... | ||

| MFD | 1310nm | um | 9.2±0.4 | 9.0±0.4 | 9.8±0.4 | |

| 1550nm | um | 10.4±0.8 | 10.1±0.5 | 9.8±0.5 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.03 | ≤0.03 | ||

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ≤0.01 | ||

| Cladding diameter | um | 125.0±0.1 | 124.8±0.1 | 124.8±0.1 | ||

| Cladding non-circularity | % | ≤1.0 | ≤0.7 | ≤0.7 | ||

| Coating diameter | um | 242±7 | 242±7 | 242±7 | ||

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | ||

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ||

| Core/cladding concentricity error | um | ≤0.6 | ≤0.5 | ≤0.5 | ||

| Curl(radius) | um | ≥4 | ≥4 | ≥4 | ||

| Fiber style | Unit | SM G652D | SM G657A1 | SM G657A2 | ||

| condition | nm | 1310/1550 | 1310/1550 | 1310/1550 | ||

| attenuation | dB/km | ≤0.36/0.23 | ≤3.5/0.21 | ≤3.5/0.21 | ||

| Dispersion | 1310nm | Ps/(nm*km) | ≤18 | ≤18 | ≤18 | |

| 1550nm | Ps/(nm*km) | ≤22 | ≤22 | ≤22 | ||

| Zero dispersion wavelength | nm | 1312±10 | 1312±10 | 1300-1324 | ||

| Zero dispersion slope | ps/(nm²×Km) | ≤0.091 | ≤0.090 | ≤0.092 | ||

| PMD Maximum Individual Fiber | [ps/√km] | ≤0.2 | ≤0.2 | ≤0.2 | ||

| PMD Design Link Value | ps/(nm²×Km) | ≤0.08 | ≤0.08 | ≤0.08 | ||

| Fiber cutoff wavelength λc | nm | >=1180,≤1330 | >=1180,≤1330 | >=1180,≤1330 | ||

| Cable cutoff wavelength λcc | nm | ≤1260 | ..... | ..... | ||

| MFD | 1310nm | um | 9.2±0.4 | 9.0±0.4 | 9.8±0.4 | |

| 1550nm | um | 10.4±0.8 | 10.1±0.5 | 9.8±0.5 | ||

| Step(mean of bidirectional measurement) | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Irregularities over fiber length and point discontinuity | dB | ≤0.05 | ≤0.05 | ≤0.05 | ||

| Difference backscatter coefficient | dB/km | ≤0.03 | ≤0.03 | ≤0.03 | ||

| Attenuation uniformity | dB/km | ≤0.01 | ≤0.01 | ≤0.01 | ||

| Cladding diameter | um | 125.0±0.1 | 124.8±0.1 | 124.8±0.1 | ||

| Cladding non-circularity | % | ≤1.0 | ≤0.7 | ≤0.7 | ||

| Coating diameter | um | 242±7 | 242±7 | 242±7 | ||

| Coating/chaffinch concentrically error | um | ≤12.0 | ≤12.0 | ≤12.0 | ||

| Coating non circularity | % | ≤6.0 | ≤6.0 | ≤6.0 | ||

| Core/cladding concentricity error | um | ≤0.6 | ≤0.5 | ≤0.5 | ||

| Curl(radius) | um | ≥4 | ≥4 | ≥4 | ||

| G657A1 fiber Environmental Characteristics (1310nm, 1500nm, &1625nm) | ||||||

| Temperature dependence Induced attenuation at | -60ºC to +85ºC | ≤0.05 | [db/Km] | |||

| Temperature-humidity cycling Induced attenuation at | -10ºC to +85ºC, 98% RH | ≤0.05 | [db/Km] | |||

| Watersoak dependence Induced attenuation at | 23ºC for 30 days | ≤0.05 | [db/Km] | |||

| Damp heat dependence Induced attenuation at | 85ºC and 85% RH | ≤0.05 | [db/Km] | |||

| for 30 days | ||||||

| Dry heat aging at | 85ºC | ≤0.05 | [db/Km] | |||

| Mechanical Specification | ||||||

| Proof test | off line | >=9.0 | [N] | |||

| >=1.0 | [%] | |||||

| >=100 | [kpsi] | |||||

| Macro-bend induced attenuation | ||||||

| 100 turns around a mandrel of 50 mm dimeter | ||||||

| 10 turns around a mandrel of 30 mm dimeter | 1550nm | ≤0.1 | [dB] | |||

| 10 turns around a mandrel of 30 mm dimeter | 1625nm | ≤0.3 | [dB] | |||

| 1 turn around a mandrel of 20 mm diameter | 1550nm | ≤0.1 | [dB] | |||

| 1 turn around a mandrel of 20 mm diameter | 1625nm | ≤0.5 | [dB] | |||

| Coating strip force | typical average force | 1.7 | [N] | |||

| peak force | >=1.3 ≤8.9 | [N] | ||||

| Daynamic stress corrosition susceptibility parameter nd(typical) | >=20 | |||||

| G657A2 fier Environmental Characteristics (1310nm, 1500nm, &1625nm) | ||||||

| Temperature dependence Induced attenuation at | -60ºC to +85ºC | ≤0.05 | [db/Km] | |||

| Temperature-humidity cycling Induced attenuation at | -10ºC to +85ºC, 98% RH | ≤0.05 | [db/Km] | |||

| Watersoak dependence Induced attenuation at | 23ºC for 30 days | ≤0.05 | [db/Km] | |||

| Damp heat dependence Induced attenuation at | 85ºC and 85% RH | ≤0.05 | [db/Km] | |||

| for 30 days | ||||||

| Dry heat aging at | 85ºC | ≤0.05 | [db/Km] | |||

| Mechanical Specification | ||||||

| Proof test | off line | >=9.0 | [N] | |||

| >=1.0 | [%] | |||||

| >=100 | [kpsi] | |||||

| Macro-bend induced attenuation | ||||||

| 10 turns around a mandrel of 30 mm dimeter | 1550mm | ≤0.3 | [dB] | |||

| 10 turns around a mandrel of 30 mm dimeter | 1625mm | ≤0.1 | [dB] | |||

| 1 turns around a mandrel of 20 mm dimeter | 1550nm | ≤0.1 | [dB] | |||

| 1 turns around a mandrel of 20 mm dimeter | 1625nm | ≤0.2 | [dB] | |||

| 1 turn around a mandrel of 15 mm diameter | 1550nm | ≤0.5 | [dB] | |||

| 1 turn around a mandrel of 15 mm diameter | 1625nm | ≤1.0 | [dB] | |||

| Coating strip force | typical average force | 1.7 | [N] | |||

| peak force | >=1.3 ≤8.9 | [N] | ||||

| Daynamic stress corrosition susceptibility parameter nd(typical) | >=20 | |||||

10. Cable marking

The cable sheath shall be marked with white characters at intervals of one meter with following information:

- Purchaser's name

- Fiber type and counts

- Cable type

- Name of manufacturer

- Country of origin

6. Length marking

Notice: cable mark is available if requested by customer.

Notice: cable mark is available if requested by customer.

- Packing Information

- Packing material: Wooden drum+ Carton box

- Packing length: standard length of cable shall be 2 km. Other cable length is also available if required by customer

12. Our certificates :

Specification

1) ISO9002

2) SGS, ROHS

3) ULE329066

4) REACH

2) SGS, ROHS

3) ULE329066

4) REACH

- Testing Lab:

| No | Device name | No | Device name |

| 1 | Optical time domain reflectometer (OTDR) | 8 | GNZV Cable Torsion Testing Machine |

| 2 | Fiber Polarization Mode Dispersion | 9 | GQNV Cable Flexing Testing Machine |

| 3 | Fiber Dispersion ,Strain Tester | 10 | GJRV Cable Winding Testing Machine |

| 4 | High Low Temperature Test Chamber | 11 | GZDV Cable Vibration Testing Machine |

| 5 | Cable Impact Testing Machine |

| Cable Water Penetration Test |

| 6 | Cable Squash Tensile Testing Machine | Fusion Splicer | |

| 7 | GWQV Cable Bending Tester | 14 | Cable Water Penetration Test Rig |

Fiber Optic Cable Mechanical Performance Testing Laboratory

- Main Testing Type: Precision Test and Mechanical Test.

- Precision Testing Machine: EXFO OTDR, EG&G PMD-440,CD-400.

- Mechanical Performance Testing : Temperature, Impact, Tensile, Bending, Torsion, Flexing, Winding, Vibration, Water Penetration, Fusion Splicer, Water Penetration.

- Our advantages:

Professional cable manufacturer.

- About 10 years experiences in cable industry.

- MOQ just 1Km.

- ISO, UL , ROSH,REACH...certifications.

- Can be customized production of fiber optic cable.

- Independent Lab with full set of testing machines.

- We have export license ,can support cable to you without profit, because we can get tax refund from Chinese government.